Understanding the Purpose of Different Pipe Fittings

Pipe fittings are vital components in plumbing systems, each serving a specific purpose. Elbows change flow direction, while tees create branch lines. Couplings join pipes together, and unions provide easy disassembly points. Reducers adjust pipe sizes, and caps and plugs seal ends. Nipples extend connections, flanges create removable joints, and adapters connect different materials. Valves control water flow throughout the system. Understanding these fittings helps you design and maintain efficient plumbing networks. By grasping their functions, you'll be better equipped to handle various plumbing challenges and optimize your system's performance. There's much more to investigate about these essential components.

Elbows: Changing Flow Direction

Elbows frequently serve as the foundation of any piping system, allowing you to change the direction of flow with ease. These versatile fittings come in various angles, with 45-degree and 90-degree elbows being the most common. When you're designing a piping layout, you'll find elbows indispensable for navigating around obstacles and optimizing space.

As you incorporate elbows into your system, it's essential to consider their impact on flow patterns and pressure changes. The bend in an elbow can create turbulence, potentially leading to pressure drops and reduced efficiency. To minimize these effects, you'll want to choose elbows with a larger radius whenever possible, as they provide smoother transitions.

You'll encounter different types of elbows, including long radius, short radius, and street elbows. Each has its specific applications, so you'll need to select the appropriate type based on your system's requirements. For instance, long radius elbows are ideal for high-flow situations, while street elbows are perfect for tight spaces. By understanding the characteristics of each elbow type, you can guarantee optimal performance and longevity in your piping system.

Tees: Creating Branch Lines

Workhorses of pipe systems, tees are essential fittings that allow you to create branch lines from a main pipe. These T-shaped connectors feature three openings, typically with one inlet and two outlets, enabling you to split flow or merge separate lines. You'll find tees in various materials, including PVC, copper, and steel, to match your specific piping needs.

Tees offer versatility in branch line configurations. You can use them to create perpendicular offshoots, allowing for distribution to multiple fixtures or equipment. They're also critical for balancing flow in parallel pipe systems. When installing tees, ensure proper alignment and secure pipe joint attachments to prevent leaks and maintain system integrity.

You'll encounter different types of tees, such as straight tees, reducing tees, and bullhead tees. Straight tees have all openings of the same size, while reducing tees feature a smaller branch outlet. Bullhead tees, with their central inlet and two side outlets, are ideal for equal flow distribution. When selecting a tee, consider factors like flow requirements, pressure ratings, and compatibility with your existing piping system to guarantee optimal performance and longevity.

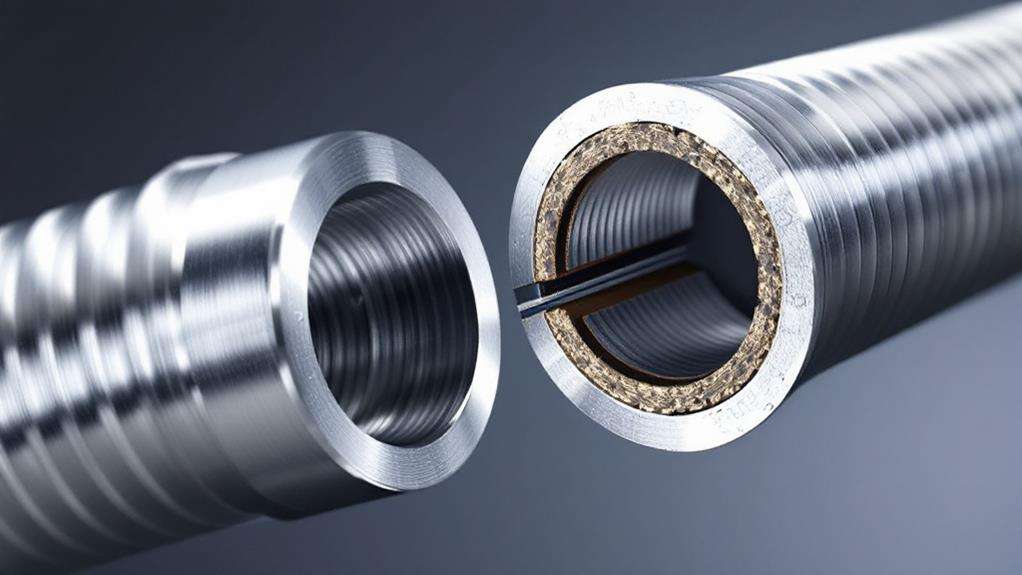

Couplings: Joining Pipes Together

While tees branch pipes, couplings serve a different purpose. Couplings are indispensable fittings that join two pipes of the same diameter end-to-end, creating a seamless connection. You'll find couplings in various materials, including PVC, copper, and steel, to match your piping system.

There are two main types of couplings: compression fittings and slip-on fittings. Compression fittings use pressure to create a watertight seal, making them ideal for high-pressure applications. You'll need to tighten the nuts on both ends to secure the pipes. Slip-on fittings, on the other hand, simply slide over the pipe ends and are secured with adhesive or soldering.

When choosing couplings, consider your pipe material and the system's pressure requirements. For example, you'd use different couplings for joining PVC pipes in a drainage system than you would for connecting copper pipes in a water supply line. Proper installation is paramount to prevent leaks, so make certain you're using the right tools and techniques for the coupling type. Remember, couplings play a pivotal role in maintaining the integrity of your piping system, so select and install them carefully.

Unions: Easy Disassembly Points

Unions stand out among pipe fittings as they offer a unique advantage: easy disassembly. Unlike other fittings that require cutting or dismantling entire sections, unions allow you to quickly disconnect pipes for maintenance or replacement. They consist of three parts: two threaded ends and a nut that joins them together.

When you need to work on your piping system, unions provide convenient access points. Their swivel action makes it simple to connect or disconnect pipes without twisting the entire line. This feature is especially useful in tight spaces or when dealing with rigid materials.

Unions offer several benefits:

- Easy maintenance and repairs

- Simplified system modifications

- Reduced downtime during servicing

- Improved overall system flexibility

Despite their convenience, unions maintain excellent pressure resistance when properly installed. You'll find them in various materials, including brass, stainless steel, and PVC, to suit different applications and environments.

When selecting unions, consider factors like pipe size, material compatibility, and pressure requirements. Remember to use unions strategically in your piping system, placing them at key points where future disassembly might be necessary. This foresight can save you time and effort during future maintenance or upgrades.

Reducers: Adjusting Pipe Sizes

Pipe size changes often require the use of reducers, essential fittings that allow you to connect pipes of different diameters. These versatile components come in various types, including concentric and eccentric reducers, each serving specific purposes in plumbing and piping systems.

When you're dealing with pipe sizing considerations, reducers play a pivotal role in maintaining proper flow and pressure throughout your system. Concentric reducers, with their symmetrical design, are ideal for vertical installations and situations where you need to minimize turbulence. On the other hand, eccentric reducers, with their offset design, are perfect for horizontal runs where you want to prevent air pockets from forming.

It's important to note that using reducers can impact your system's performance. You'll need to factor in pressure drop calculations when incorporating these fittings into your design. As the pipe diameter changes, so does the fluid velocity and pressure, which can affect overall system efficiency. By carefully selecting the appropriate reducer type and size, you'll facilitate smooth transitions between pipe sections, minimize energy losses, and maintain optimal flow characteristics throughout your piping network.

Caps and Plugs: Sealing Ends

When it comes to sealing pipe ends, caps and plugs are indispensable fittings in any plumbing or piping system. These simple yet essential components serve to close off open pipe ends, preventing leaks, contamination, and unwanted flow. You'll find caps and plugs in various materials, sizes, and designs to suit different applications and pressure ratings.

Caps are typically used for permanent sealing, while plugs offer a more temporary solution. When selecting caps or plugs, consider factors such as:

- Material compatibility with the pipe and fluid

- Pressure ratings of the system

- Corrosion resistance requirements

- Ease of installation and removal

You'll need to make certain that the cap or plug you choose can withstand the system's pressure and temperature conditions. For high-pressure applications, you might opt for welded caps or threaded plugs with appropriate pressure ratings. In corrosive environments, select materials with excellent corrosion resistance, such as stainless steel or specialized plastics.

Remember that proper installation is of the utmost importance for effective sealing. Use thread sealants or gaskets as needed, and always follow manufacturer guidelines. By choosing the right caps and plugs, you'll effectively seal pipe ends and maintain the integrity of your piping system.

Nipples: Extending Pipe Connections

Although they may seem simple, nipples play a crucial role in extending pipe connections and bridging gaps in piping systems. These short pipe segments come in various lengths and diameters, allowing you to customize your piping layout with precision. Nipples feature threaded connections on both ends, making them versatile for joining different fittings or extending existing pipes.

You'll find nipples particularly useful when you need to create pipe extensions or adjust the spacing between components. They're available in different materials, including brass, steel, and PVC, to match your specific plumbing needs. When selecting a nipple, consider its length, diameter, and thread type to guarantee compatibility with your existing system.

Nipples come in several styles, such as close nipples, which have little to no unthreaded area between the ends, and long nipples, which provide greater extension. You can use them to connect valves, unions, or other fittings, as well as to create custom-length pipe sections. By incorporating nipples into your piping system, you'll gain flexibility in design and the ability to make precise adjustments to your layout.

Flanges: Removable Pipe Connections

Workhorses of industrial piping systems, flanges provide a reliable method for creating removable connections between pipe sections. They're essential components in applications where you need to disassemble pipes for maintenance, inspection, or replacement. Flanges consist of two mating surfaces that are bolted together, with a gasket sandwiched between them to safeguard a leak-proof seal.

When selecting flanges, you'll need to ponder factors such as pressure rating, temperature, and chemical compatibility. Proper flange orientation is pivotal for ensuring a secure connection and preventing leaks. You'll also need to choose appropriate gasket materials based on the specific application and operating conditions.

Some common types of flanges you might encounter:

- Weld neck flanges: Offer excellent strength and are ideal for high-pressure applications

- Slip-on flanges: Easy to install and adjust, suitable for lower pressure systems

- Blind flanges: Used to seal off the end of a piping system

- Lap joint flanges: Allow for easy rotation during installation, reducing alignment issues

Adapters: Connecting Different Materials

Nearly every piping system requires adapters at some point to connect different materials or pipe sizes. Adapters serve as vital components in guaranteeing pipe material compatibility and sustaining efficient flow rates throughout your system. You'll encounter various types of adapters, each designed for specific applications.

When selecting adapters, consider the materials you're connecting and the potential for chemical reactions or corrosion. For instance, joining copper to steel may require a dielectric adapter to prevent galvanic corrosion. Flow rate considerations are also essential, as poorly chosen adapters can create restrictions or turbulence that impact system performance.

Common adapter types include threaded, flanged, and compression fittings. Threaded adapters are versatile but may introduce slight leakage risks. Flanged adapters offer secure connections for larger pipes, while compression fittings are ideal for quick, tool-free installations.

You'll also find specialty adapters like reducing couplings for changing pipe diameters, unions for easy disassembly, and expansion joints to accommodate thermal movement. By choosing the right adapter, you'll guarantee a seamless transition between different materials, maintain system integrity, and optimize flow characteristics throughout your piping network.

Valves: Controlling Water Flow

Valves stand out as vital components in any piping system, allowing you to control the flow of water with precision. They're essential for managing water distribution, regulating pressure, and ensuring safety in plumbing networks. You'll find various types of valves, each designed for specific purposes and applications.

When selecting valves for your piping system, consider factors such as:

- The type of fluid being controlled

- Operating pressure and temperature ranges

- Required flow rates and pressure drops

- Frequency of operation and maintenance needs

Gate valves, ball valves, and globe valves are common choices for residential and commercial plumbing. For more specialized applications, you might need butterfly valves or check valves. Water pressure regulation is indispensable in maintaining system integrity and preventing damage to pipes and fixtures. Flow measurement devices, such as flow meters, can be integrated with valves to monitor and control water usage accurately.

You'll often find valves used in conjunction with other pipe fittings to create complex systems. By understanding the function and limitations of different valve types, you can design efficient and reliable plumbing networks that meet your specific needs.