How to Prevent Pump Burnout With Proper Maintenance

To prevent pump burnout, start by understanding its causes and investing in quality equipment. Regularly inspect and clean your pump, guaranteeing proper priming and sustaining optimal water levels. Keep electrical connections safe and grounded, and winterize your pump for storage. During operation, monitor performance indicators and follow a professional maintenance schedule. Always ensure the pump is submerged when running to prevent dry operation and overheating. Proper care extends your pump's lifespan, saves money, and prevents unexpected failures. By implementing these strategies, you'll markedly reduce the risk of burnout and keep your pump running smoothly for years to come.

Understanding Pump Burnout

Frustration often accompanies the experience of pump burnout, a common issue that plagues many water feature enthusiasts. Pump burnout occurs when your pump fails to function at full capacity or dies prematurely, typically due to running dry. This leads to overheating and damage, especially in submersible pumps that aren't fully submerged.

You're more likely to encounter burnout with low-quality pumps due to poor construction and materials. However, even high-quality pumps can suffer if not properly cared for. Improper installation, frequent on-off cycles, and neglecting maintenance all contribute to burnout risk.

To protect your pump, ensure it's always submerged when running. This is necessary for maintaining proper water pressure and preventing dry operation. If you're using well water, be extra vigilant about water levels, as they can fluctuate more than in other sources.

Consider investing in a pump with an automatic low water shut-off feature. This smart technology will turn off your pump before it runs dry, drastically reducing burnout risk. By understanding the causes of pump burnout and taking preventive measures, you'll extend your pump's life and enjoy your water feature for years to come.

Regular Inspection and Cleaning

Now that you understand pump burnout, let's focus on a key prevention strategy: regular inspection and cleaning. To keep your water pump running smoothly, you'll need to establish a routine maintenance schedule.

Start by regularly inspecting your pump for any visible signs of wear, damage, or debris buildup. This proactive approach can help you catch potential issues before they escalate. When cleaning your pump, focus on both the exterior and interior components. Use a soft cloth and warm water to thoroughly remove accumulated dirt, grime, and mineral deposits.

For a more thorough cleaning, you'll need to disassemble the pump according to the manufacturer's instructions. This allows you to access and clean the impeller, housing, and other internal parts. Use a soft-bristled brush or a mild detergent solution to gently scrub these components, taking care not to damage any delicate parts.

After cleaning, rinse all components with clean water and dry them completely before reassembling the pump. This step is essential to prevent corrosion, especially in well pumps that are constantly exposed to water. By following these cleaning and inspection procedures, you'll markedly reduce the risk of pump burnout and extend the life of your equipment.

Proper Priming Techniques

Consistently priming your pump correctly is critical for preventing burnout and guaranteeing excellent performance. To properly prime your submersible pump, start by submerging it completely underwater and tilting it to release any trapped air. This technique helps eliminate air pockets that can lead to pump burnout and reduced efficiency.

Before installation, you should prime your pump by running it under a faucet or hose. This step affirms the impeller chamber is filled with water, preventing dry running and potential damage. Remember to follow the manufacturer's instructions carefully, as proper priming techniques vary depending on the specific pump model.

When priming, make sure to allow all air to escape from the pump. This practice extends your pump's lifespan by preventing overheating and damage caused by air remaining in the impeller chamber. By taking the time to prime your pump correctly, you'll avoid premature failure and maintain peak performance.

Don't neglect this vital maintenance step, as improper priming can drastically shorten your pump's overall lifespan. By consistently using proper priming techniques, you'll affirm your submersible pump operates efficiently and lasts longer, saving you time and money in the long run.

Maintaining Optimal Water Levels

Why is maintaining ideal water levels critical for preventing pump failure? Proper water levels guarantee your pump operates efficiently and safely, preventing dry running and overheating. When water levels drop too low, your pump risks burnout, leading to costly repairs or replacements.

To sustain optimal water levels, you'll need to monitor them regularly. Keep an eye on your well pump's intake, making certain it remains fully submerged. If you notice levels dropping, add water promptly to protect your pump. Installing a low water cut-off switch is an excellent preventive measure, automatically shutting off the pump when water levels become dangerously low.

Don't forget to clean the pump intake area regularly. This simple maintenance task helps maintain proper water flow and cooling, further safeguarding your pump from burnout. Additionally, adjust your water level control system to maintain the ideal depth for your specific pump model.

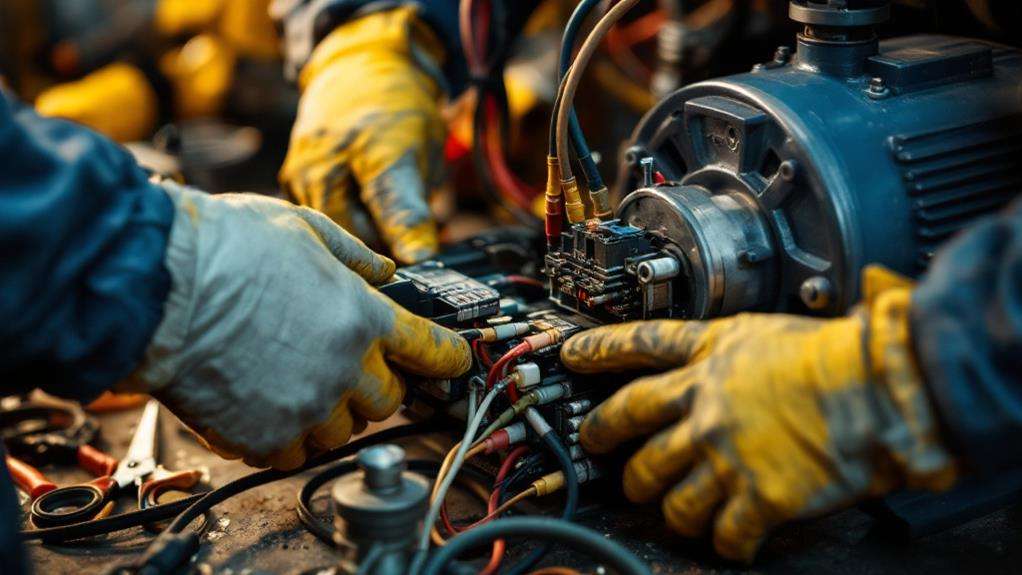

Electrical Connection Safety

Electrical connection safety is paramount in preventing pump burnout. You'll need to confirm all electrical connections are properly grounded and use a GFCI outlet to protect against electrical shocks and potential pump damage. Regularly inspect your pump's wiring and connections for signs of wear, corrosion, or damage to avoid short circuits that could lead to burnout.

Install appropriate circuit breakers or fuses to safeguard your pump from power surges and electrical overloads, which can cause premature failure. When setting up your pump, use only high-quality, water-resistant electrical components designed for submerged installations. This approach will maintain safety and prevent burnout in wet environments.

It's essential to consult a licensed electrician to verify that your pump's electrical setup meets local codes and safety standards. This step substantially reduces the risk of pump-related accidents and ensures your installation is up to par. By following these electrical safety measures, you'll protect your pump from burnout and extend its lifespan. Remember, proper electrical connection safety isn't just about preserving your equipment – it's also about protecting yourself and others from potential hazards associated with submerged pumps.

Winterization and Storage

Proper winterization and storage are critical steps in preventing pump burnout during the colder months. As temperatures drop, it is crucial to remove your well pump from the water and store it correctly to avoid damage from freezing. Before storage, drain all remaining water from the pump and clean it thoroughly. This simple step can significantly extend your pump's lifespan.

Choose a dry, temperature-controlled environment for storage to protect your pump from corrosion and other environmental factors. Wrap or cover the pump to shield it from dust, debris, and moisture that could impair its function. Remember, proper storage is key to maintaining your pump's efficiency and longevity.

When spring arrives, do not rush to reinstall your pump. First, perform an extensive inspection and test run to verify it is ready for the upcoming season. This precautionary measure can help you identify any potential issues before they become major problems.

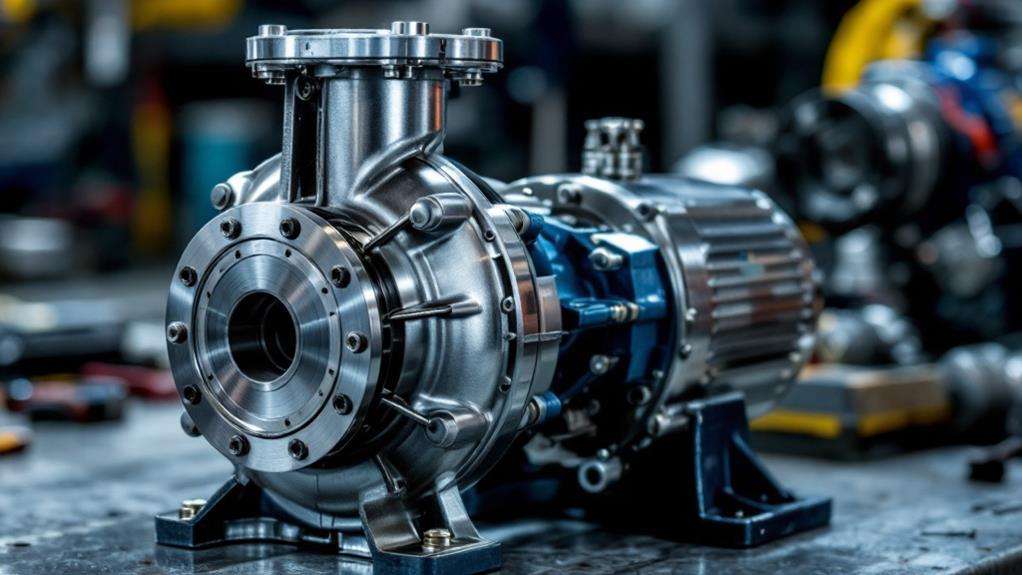

Choosing Quality Pumps

Selecting a high-quality pump is one of the most effective ways to prevent burnout. When you're in the market for a new pump, consider investing in reputable brands like TotalPond, which offer superior longevity compared to cheaper alternatives. These high-quality pumps often come with features specifically designed to prevent burnout, such as Low Water Shut-Off, which stops the pump from running dry.

When choosing a pump, guarantee it's appropriate for your specific application. Look for the right flow rate, pressure, and energy efficiency to optimize performance and extend its lifespan. Proper installation is indispensable, so pay attention to electrical connections and always use a GFCI outlet for safety.

Don't overlook the importance of warranties and manufacturer support. A thorough warranty can provide peace of mind and guidance on proper maintenance practices. By choosing a quality pump and following the manufacturer's recommendations, you'll substantially reduce the risk of burnout and extend your pump's life. Remember, while quality pumps may cost more upfront, they often save you money in the long run through improved performance and reduced maintenance needs.

Monitoring Performance Indicators

Once your pump is installed and running, vigilant monitoring of key performance indicators becomes essential in preventing burnout. Keep a close eye on your pump's energy consumption, as sudden increases may signal wear, impeller imbalance, or bearing issues. Track runtime and cycle frequency to avoid excessive on/off cycling, which can lead to premature wear.

Regularly observe your pump's discharge pressure and flow rate. Changes in these metrics could indicate problems like blockages, leaks, or impeller damage, all of which can impact pump performance. Listen carefully for unusual noises or vibrations, as these are often early warning signs of mechanical issues.

Don't forget to monitor your pump's temperature. Overheating can quickly lead to burnout if left unchecked. By staying attentive to these indicators, you'll be able to identify potential problems before they escalate.

Professional Maintenance Schedule

While regular monitoring is indispensable, it's not a substitute for professional proficiency. To prevent well pump burnout, you should schedule professional maintenance inspections at least once or twice a year. These visits are vital for identifying and addressing potential issues before they escalate into major problems.

During these inspections, a licensed technician will thoroughly examine your pump, motor, electrical connections, and overall system performance. They'll also assess your water quality and the pressure switch functionality. You should implement their recommended maintenance tasks, which may include cleaning, lubricating, and replacing worn components to keep your pump operating efficiently.

Between professional visits, continue monitoring your pump's performance. Pay attention to changes in water pressure, flow, or energy consumption, as these could indicate underlying issues. If you notice any irregularities, don't hesitate to call a professional.

Maintain complete service records to track your pump's history. This documentation will help you better plan for future repairs or replacement, ensuring your water well system remains in top condition. By following a professional maintenance schedule, you'll markedly reduce the risk of pump burnout and extend your well pump's lifespan.