How to Choose the Best Pump Accessories for Your Plumbing System

To choose the best pump accessories for your plumbing system, start by understanding your pump's classification and specific needs. Consider essential components like float switches, check valves, and electrical accessories that match your system's requirements. Select appropriate pump couplings and bases to guarantee stability and efficient operation. Don't forget to factor in energy efficiency and long-term cost-effectiveness when making your choices. Proper installation and regular maintenance are imperative for peak performance. By carefully evaluating each accessory's role and compatibility with your system, you'll be well on your way to creating a sturdy and dependable plumbing setup.

Understanding Pump Classification

Pumps, the workhorses of plumbing systems, fall into two main categories: automatic and non-automatic. Understanding these classifications is essential when selecting the right pump and accessories for your water management needs.

Automatic pumps come equipped with built-in float switches, simplifying installation and operation. These switches control the pump's on/off cycles based on water levels, making them ideal for straightforward applications. On the other hand, non-automatic pumps offer more flexibility, allowing you to customize your setup with external float switches or electronic controllers.

When choosing accessories for non-automatic pumps, you'll encounter various float switch options. Tethered or variable switches, vertical switches, and diaphragm pressure switches each have unique installation requirements and capabilities. Consider your specific needs when selecting the appropriate switch type.

For advanced control and added protection, electronic controllers are worth exploring. These devices offer features like flood protection alerts and more sophisticated pump management options compared to basic float switches.

Essential Float Switch Options

When selecting accessories for your non-automatic pump, you'll need to choose from several essential float switch options. These float switches are pivotal for managing water levels and preventing your pump from running dry.

For confined spaces and lower water levels, consider a vertical float switch. This compact option is ideal when traditional tethered float switches won't fit. If you need more flexibility in installation, tethered or variable float switches offer adaptability where standard floats might not work.

If you're looking for an alternative to mechanical designs, diaphragm pressure float switches use pressure changes to activate your sump pump. These can be particularly useful in certain water source scenarios.

For advanced protection, electronic controllers provide additional flood safeguards and alerts beyond basic float switches. These pump accessories can offer peace of mind and enhanced functionality.

When choosing float switches, consider the specific requirements of your plumbing system. Factors like space constraints, water level variations, and desired features should guide your decision. Remember, selecting the right float switch is pivotal for efficient water management and protecting your pump from dry running. Pair your chosen float switch with a reliable one-way valve to guarantee optimal performance of your plumbing system.

Check Valves and Backflow Prevention

Another key component in your plumbing pump setup is the check valve, which plays a pivotal role in backflow prevention. This device guarantees that water flows in only one direction, preventing it from reversing course and potentially damaging your pump or contaminating your water supply.

When selecting a check valve, contemplate the type of pump you're using and its performance requirements. Different types of pumps may need specific check valves to function ideally. For instance, submersible pumps often require spring-loaded check valves, while centrifugal pumps might work better with swing check valves.

Install the check valve on the discharge pipe, close to the pump discharge. This placement helps maintain pressure in the system and reduces the likelihood of water hammer. Back pressure valves are another option to consider, especially in systems with high head pressure or long discharge lines.

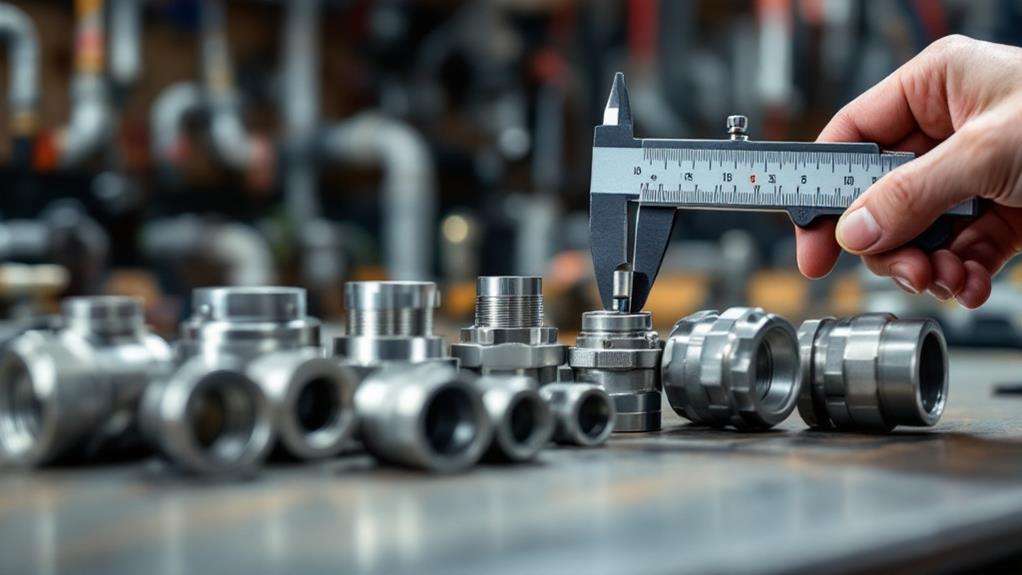

Remember that proper sizing is indispensable for effective backflow prevention. A valve that's too small can restrict flow and reduce pump efficiency, while one that's too large may not close properly. Always consult your pump's specifications and local plumbing codes when choosing and installing check valves to guarantee optimal performance and compliance.

Electrical Requirements and Considerations

For plumbing pump installations, electrical requirements and considerations are essential to guarantee safe and efficient operation. When choosing pump accessories, you'll need to factor in the electrical aspects to verify compatibility and performance. Make sure you understand the voltage and amperage requirements of your pumps, as these will impact your electrical setup and safety measures.

Consider these key factors when addressing electrical requirements:

- Power supply: Verify that your electrical system can handle the pump's power demands, including voltage, phase, and frequency.

- Control panels: Select appropriate control panels to manage pump operation, monitoring, and protection against electrical faults.

- Wiring and connections: Use proper wiring and connections suitable for the pump's power requirements and environmental conditions.

Valves and other accessories play a pivotal role in managing pressure and flow rate, but they may also have electrical components. When selecting these accessories, confirm they're compatible with your pump's electrical specifications. Always consult local electrical codes and regulations to ensure compliance. By carefully considering these electrical factors, you'll create a more efficient and reliable plumbing system that operates safely and effectively.

Choosing Appropriate Pump Couplings

After addressing electrical considerations, you'll need to select the right pump couplings for your system. Choosing appropriate couplings is pivotal for optimal performance and reliability. You'll encounter various types, each suited for different applications.

Flexible shaft couplings are ideal when you need to accommodate misalignment and absorb vibration. They're particularly useful in systems with constant pressure or where check valves are present. For high-torque applications, rigid shaft couplings provide a secure connection, ensuring effective power transmission from the driver to the pump.

If you anticipate frequent maintenance, consider split shaft couplings. These allow for easy pump removal without disturbing the rest of the plumbing system, including discharge components like Pressure Relief valves or Pulsation Dampeners.

Hydraulic couplings offer dependable engagement and disengagement, making them suitable for systems with Griffco Valves or other pressure-sensitive components. For applications where leaks are a concern, magnetic couplings provide a safe, seal-less option.

When selecting a coupling, consider factors such as pump size, speed, and specific application requirements. The right choice will enhance your system's efficiency, minimize downtime, and guarantee smooth operation of Relief Valves and other critical components.

Selecting the Right Pump Base

Once you've chosen the appropriate couplings, it's time to focus on selecting the right pump base. The pump base plays a vital role in guaranteeing your plumbing system operates efficiently and safely. It provides stability and support for your pump, helping to maintain proper alignment and reduce vibrations that can affect performance.

When selecting a pump base, you'll need to take into account several factors:

- Water level: Ensure the base can accommodate fluctuations in the sump pit's water level.

- System pressure: Choose a base that can withstand the expected pressure in your plumbing system.

- Pump to pump compatibility: If you're installing multiple pumps, select a base that allows for proper spacing and connections.

You'll also need to know the dimensions of your pump and the available space in your installation area. Ponder bases with calibration columns for easy maintenance and adjustment. If you're dealing with a high-pressure system, opt for a reinforced base to prevent warping or damage.