How to Choose the Best Pipe for Underground Use

To choose the best pipe for underground use, you'll need to ponder several key factors. Start by evaluating your specific application, such as water supply or sewage, and determine the required pipe size and flow rate. Assess your soil conditions, including composition, pH, and water table level, as these can impact pipe performance. Compare common materials like PVC, HDPE, ductile iron, and concrete, contemplating their strengths and weaknesses. Don't forget to factor in installation methods, local regulations, and long-term cost analysis. By carefully examining these aspects, you'll be better equipped to select the ideal pipe for your underground project. Plunge deeper to uncover more pivotal details.

Common Underground Pipe Materials

Underground pipes serve as the hidden arteries of our infrastructure. When selecting materials for these essential conduits, you'll need to ponder various factors, including pipe strength and pipe flexibility. The most common materials for underground pipes include PVC, HDPE, ductile iron, and concrete.

PVC pipes are lightweight, corrosion-resistant, and offer excellent pipe flexibility. They're ideal for water and sewer lines in residential and commercial applications. HDPE pipes share similar benefits but provide even greater flexibility and are often used in gas lines and industrial settings.

Ductile iron pipes boast superior pipe strength and durability, making them suitable for high-pressure water mains and areas with heavy surface loads. While less flexible than plastic options, they can withstand significant external forces.

Concrete pipes are known for their exceptional strength and longevity. They're commonly used in large-diameter stormwater and sewer systems. However, they lack the flexibility of plastic pipes and can be prone to cracking in unstable soil conditions.

Each material has its strengths and weaknesses, so you'll need to carefully evaluate your specific project requirements, soil conditions, and local regulations to determine the best underground pipe material for your needs.

Factors Influencing Pipe Selection

Several key factors influence your choice of underground pipes. You'll need to contemplate the specific application, soil conditions, and local regulations before making a decision. The pipe's intended use, whether for water supply, sewage, or drainage, will dictate certain requirements.

Pipe size requirements are imperative. You must ensure the selected pipe can handle the expected volume and pressure of the fluid it'll transport. Flow rate considerations go hand-in-hand with size, as you'll need to calculate the optimal diameter to maintain efficient flow without excessive pressure loss.

The soil type and composition where you'll install the pipe are fundamental factors. Acidic or corrosive soils may require more resistant materials. You should also account for soil stability and potential ground movement, which could affect the pipe's structural integrity over time.

Climate conditions play a role too. Extreme temperatures, freeze-thaw cycles, and moisture levels can impact pipe performance and longevity. Additionally, installation depth and traffic loads above the pipe are important considerations.

Lastly, don't forget about cost-effectiveness. While initial expenses are important, factor in long-term maintenance, replacement costs, and expected lifespan to make the most economical choice for your underground pipe project.

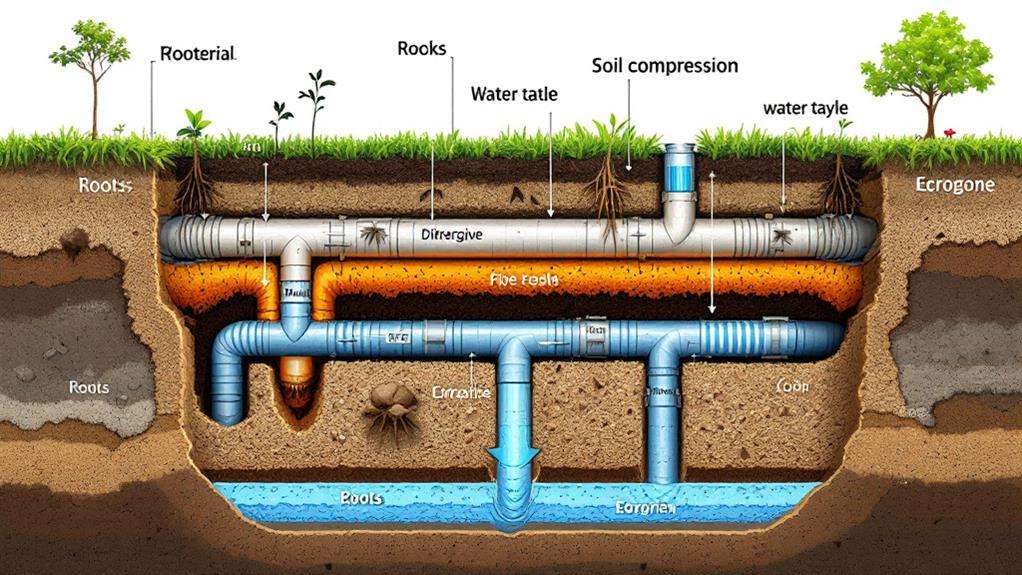

Soil Considerations and Impact

When selecting pipes for underground use, you must carefully assess the soil conditions at your installation site. The soil composition plays a fundamental role in determining the type of pipe that will perform best and last longest. Clay soils, for instance, can be corrosive and may require pipes with enhanced protective coatings. Sandy soils, on the other hand, might necessitate pipes with greater structural integrity to withstand potential shifting.

Consider the water table level in your area, as it can significantly impact pipe performance. High water tables can lead to buoyancy issues, potentially causing pipes to float or shift. In such cases, you'll need to choose pipes with appropriate weight or anchoring systems. Additionally, fluctuating water tables can create soil movement, which may stress pipe joints and connections.

Soil pH is another critical factor. Acidic soils can corrode metal pipes, while alkaline soils might degrade certain plastic materials. You should also evaluate soil temperature variations, as extreme changes can affect pipe expansion and contraction. By thoroughly analyzing these soil considerations, you'll be better equipped to select pipes that can withstand the specific underground conditions at your site, ensuring longevity and ideal performance.

Installation Methods and Requirements

Once you've selected the appropriate pipes for your underground project, it's essential to focus on proper installation methods and requirements. Start by developing comprehensive pipe layout strategies that account for the terrain, soil conditions, and future maintenance needs. Consider factors like slope, depth, and potential obstacles when planning your pipe routes.

Underground access planning is crucial for long-term maintenance and repairs. Install access points at strategic locations, such as manholes or cleanouts, to allow for future inspections and servicing. Ensure these access points are easily reachable and properly sealed to prevent infiltration.

When installing pipes, follow manufacturer guidelines and local regulations. Prepare a proper bedding material to support the pipes and prevent settling. Use appropriate backfill materials and compaction techniques to guarantee stability and protect the pipes from damage. Install pipe joints correctly, using recommended sealants or gaskets to prevent leaks.

Implement trench safety measures to protect workers during installation. Use trench boxes or shoring systems when necessary, and follow OSHA guidelines for excavation safety. Finally, conduct thorough testing and inspections before backfilling to guarantee the system's integrity and functionality.

Cost and Longevity Analysis

A crucial cost and duration analysis is essential when selecting pipes for subterranean application. You'll need to ponder both initial expenses and long-term value to make an informed decision. Begin by comparing the upfront costs of different pipe materials, such as PVC, HDPE, and ductile iron. Don't forget to factor in installation expenses, which can vary drastically depending on the material's heft and handling requirements.

Next, evaluate the longevity of each pipe type. While some materials may have higher initial costs, they could prove more economical over time due to their extended lifespan and reduced maintenance requirements. For instance, HDPE pipes might be pricier upfront but offer excellent durability and resistance to corrosion, potentially lowering long-term expenses.

Consider the pipe's intended use and environmental conditions when examining maintenance requirements. Some materials may need more frequent inspections or repairs, impacting overall costs. Additionally, factor in potential replacement costs and the ease of future modifications. By carefully weighing these aspects, you'll be able to choose the most cost-effective and durable pipe solution for your underground project.