How to Avoid Common Mistakes in Pipe Installation

To avoid common mistakes in pipe installation, you'll need to focus on proper sizing, support, and material selection. Guarantee you calculate required flow rates accurately and install adequate hangers to prevent sagging. Choose the right pipe material for your specific application and environmental conditions. Always conduct thorough pressure tests to identify leaks early. Account for expansion and contraction in your design, and use correct joining techniques for each type of pipe. Don't forget to insulate pipes properly and comply with local building codes. By paying attention to these key areas, you'll be well on your way to a successful installation. There's much more to ponder for a truly professional job.

Proper Pipe Sizing

One of the most critical aspects of pipe installation is proper sizing. When you're planning your plumbing system, it's crucial to analyze the specific needs of your project. Undersized pipes can lead to reduced water pressure, while oversized pipes may result in unnecessary costs and inefficient water usage.

To determine the correct pipe size, you'll need to investigate several factors. First, calculate the required flow rate for your system. This involves evaluating the number of fixtures, their water demands, and peak usage times. Once you have this information, you can use flow rate calculations to determine the appropriate pipe diameter.

Don't forget to account for pipe material compatibility when sizing your pipes. Different materials have varying flow characteristics and pressure ratings. For example, PVC pipes have smoother interior surfaces than copper, which can affect flow rates.

Contemplate future expansion needs when sizing your pipes. It's frequently more cost-effective to install slightly larger pipes initially than to replace them later. Consult local building codes and industry standards to guarantee compliance with regulations. By taking these factors into account, you'll avoid common sizing mistakes and create a more efficient, long-lasting plumbing system.

Adequate Support and Anchoring

While proper pipe sizing guarantees efficient water flow, it's equally important to focus on adequate support and anchoring. Failing to provide sufficient support for your pipes can lead to sagging, misalignment, and potential leaks. You'll want to install pipe hangers and supports at regular intervals, confirming they're strong enough to bear the weight of the pipes and their contents.

When anchoring pipes, consider the material's thermal expansion and contraction properties. Use flexible connections or expansion joints to accommodate these movements and prevent stress on the system. Don't forget to account for pipe vibrations, especially in areas with pumps or other equipment. Install vibration isolators to minimize noise and protect your pipes from excessive movement.

Proper support and anchoring also play a pivotal role in corrosion prevention. By keeping pipes off the ground and away from moisture-prone areas, you'll reduce the risk of external corrosion. Use corrosion-resistant materials for your supports and confirm they're compatible with the pipe material to avoid galvanic corrosion. Remember to inspect your supports regularly and replace them if you notice any signs of wear or damage.

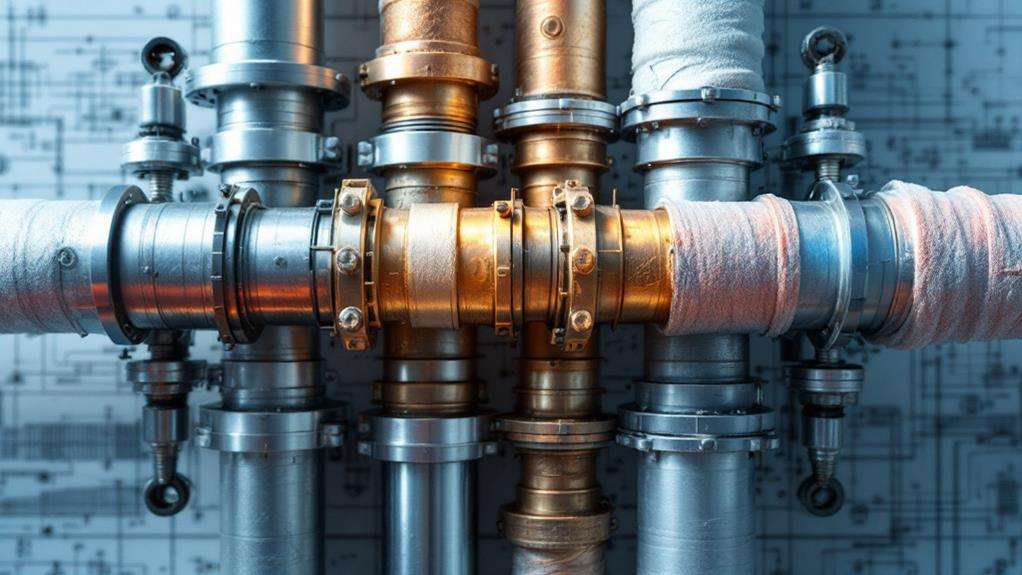

Correct Material Selection

Choosing the right pipe material is essential for the longevity and efficiency of your plumbing system. You'll need to ponder factors such as the type of fluid being transported, environmental conditions, and pressure requirements. Different materials offer varying levels of corrosion prevention, which is pivotal for maintaining the integrity of your pipes over time.

For instance, PVC pipes are excellent for cold water applications and resist chemical corrosion, while copper pipes are ideal for hot water systems due to their heat resistance. Stainless steel pipes offer superior durability and corrosion resistance, making them suitable for harsh environments. When selecting pipe materials, don't disregard flow dynamics. Smooth interior surfaces, like those found in PEX pipes, diminish friction and improve overall system productivity.

Contemplate the specific needs of your project. If you're dealing with aggressive chemicals, CPVC pipes might be the best choice. For underground installations, ductile iron pipes offer excellent strength and longevity. Remember, improper material selection can lead to premature pipe failure, leaks, and costly repairs. Always consult local building codes and industry standards to guarantee your chosen materials comply with regulations and are appropriate for your specific application.

Pressure Testing Procedures

Pressure testing is a pivotal step in pipe installation that you can't afford to skip. It guarantees the integrity of your piping system and helps prevent costly leaks and failures down the line. When conducting pressure tests, you'll need to follow proper procedures to ensure accurate results and maintain safety standards.

To perform an effective pressure test, follow these key steps:

- Isolate the section of piping you're testing

- Fill the system with water or air, depending on the test type

- Gradually increase pressure to the specified level

- Monitor pressure for the required duration

During the test, pay close attention to any pressure drops, which may indicate leaks. Leak identification is paramount for pinpointing potential weak points in your system. If you spot any issues, address them immediately to prevent further damage.

Remember that pressure testing isn't just about finding leaks; it's also an essential part of corrosion prevention. By identifying and fixing weak spots early, you'll extend the life of your piping system and reduce the risk of corrosion-related failures. Always document your pressure test results for future reference and compliance purposes.

Expansion and Contraction Considerations

After ensuring your pipes can withstand pressure, you'll need to account for their natural tendency to expand and contract. Pipes respond to temperature changes, and failing to evaluate this can lead to serious problems. As thermal fluctuations occur, pipes may shift, causing stress on joints and potentially leading to leaks or breaks.

To address this issue, install expansion joints or loops in your piping system. These components allow for movement without compromising the integrity of the pipes. Analyze the material of your pipes, as different materials have varying expansion rates. For example, PVC expands more than steel, so you'll need to plan accordingly.

Don't forget to factor in soil conditions when planning for expansion and contraction. Different soil types can affect how much your pipes move, especially in areas with freeze-thaw cycles. Use proper bedding and backfill materials to provide support and minimize stress on the pipes.

When installing pipes in buildings, allow for movement at wall penetrations and floor crossings. Use sleeves or flexible connections to accommodate expansion and contraction. By anticipating these natural movements, you'll drastically reduce the risk of pipe failure and extend the lifespan of your plumbing system.

Joint and Fitting Techniques

In light of proper pipe installation, becoming proficient in joint and fitting techniques is essential. You'll need to master proper joint alignment and appropriate sealing techniques to guarantee a leak-free and durable system. Start by carefully inspecting all components for damage or defects before assembly. Clean the joining surfaces thoroughly to remove any dirt, debris, or moisture that could compromise the seal.

When connecting pipes, follow these key steps for successful joints:

- Measure and mark the pipe accurately for precise cuts

- Use the correct tools to create clean, square ends

- Apply appropriate lubricant or primer as recommended by the manufacturer

- Align the pipes carefully before making the final connection

For threaded joints, use thread sealant or tape to prevent leaks. With solvent-welded joints, apply the right amount of cement and join the parts quickly before it sets. When working with compression fittings, ensure the ferrule is properly seated and tightened to the manufacturer's specifications. Remember, overtightening can be just as problematic as undertightening. By perfecting these techniques, you'll drastically reduce the risk of leaks and system failures in your pipe installation projects.

Insulation and Protection Methods

Concerning pipe installation, insulation and protection techniques play a crucial part in guaranteeing system durability and effectiveness. You'll want to choose the right insulation materials based on your specific needs, considering factors like temperature range, moisture exposure, and environmental conditions. For thermal efficiency, use materials like fiberglass, foam, or mineral wool, making sure they're properly sized and fitted around pipes.

Don't forget about moisture control. Apply vapor barriers when necessary to prevent condensation and potential corrosion. For outdoor pipes, use weather-resistant jacketing to protect against UV rays and harsh elements. In areas prone to freezing, consider heat tracing or pipe heating cables to prevent burst pipes during cold spells.

When installing insulation, avoid compressing it, as this reduces its effectiveness. Seal all joints and seams properly to maintain a continuous insulation barrier. For underground pipes, use protective coatings or wraps to guard against soil corrosion and root intrusion. In areas with high foot traffic or potential impacts, install protective covers or sleeves to prevent damage. Regularly inspect and maintain your insulation and protection systems to make sure they continue to perform as intended, replacing damaged sections promptly to avoid compromising the entire system.

Code Compliance and Inspections

While proper insulation and protection are indispensable, they're only part of the equation. Guaranteeing your pipe installation complies with local codes and passes inspections is equally important. Before you begin any project, familiarize yourself with municipal regulations and obtain all necessary permits required.

Code compliance isn't just about following rules; it's about safety and longevity. Inspections serve as vital checkpoints throughout the installation process. To stay on top of code requirements and inspections:

- Research local building codes specific to pipe installations

- Schedule inspections at key stages of the project

- Maintain detailed documentation of your work

- Be prepared to make adjustments based on inspector feedback

Don't view inspections as obstacles; they're opportunities to ensure your work meets the highest standards. Remember, code requirements can vary drastically between jurisdictions, so what's acceptable in one area may not be in another. Stay informed about updates to local regulations, as they can change over time.