Dealing With Pipe Expansion and Contraction in Plumbing

To deal with pipe expansion and contraction in plumbing, you'll need to understand thermal dynamics and implement preventive measures. Start by selecting appropriate pipe materials and considering their thermal properties. Install expansion joints or loops to accommodate movement, and use proper supports and anchors to distribute stress. Insulate pipes to minimize temperature fluctuations, and design your system with thermal stress in mind. Regular maintenance and inspections are vital to catch issues early. By addressing expansion and contraction, you'll prevent leaks, bursts, and costly water damage. There's much more to examine about this pivotal aspect of plumbing system management.

Understanding Thermal Expansion and Contraction

In the world of plumbing, thermal expansion and contraction are paramount concepts you'll need to grasp. These phenomena occur due to temperature changes, causing pipes to expand when heated and contract when cooled. As a plumber or homeowner, understanding this process is indispensable for preventing leaks, breaks, and other plumbing issues.

When you're dealing with pipe thermal gradient, you're essentially addressing the temperature difference between the pipe's interior and exterior. This gradient can lead to uneven expansion or contraction, potentially causing stress on the pipe material. Ambient temperature fluctuations also play a significant role in this process. As the surrounding air temperature changes throughout the day or seasonally, your pipes will respond accordingly.

You'll need to take into account the pipe material when planning for expansion and contraction. Different materials, such as copper, PVC, or steel, have varying expansion rates. You'll also want to factor in the pipe's length, as longer pipes will experience more noticeable changes. By accounting for these factors and implementing proper installation techniques, you can minimize the risk of damage and ensure your plumbing system remains functional and efficient over time.

Factors Affecting Pipe Movement

Now that you've grasped the basics of thermal expansion and contraction, it's time to investigate the factors that influence pipe movement. Temperature changes remain the primary cause, but several other elements can contribute to pipe displacement.

Material properties play a pivotal role in how pipes respond to temperature fluctuations. Different materials have varying coefficients of thermal expansion, with metals like copper expanding more than plastics like PVC. The pipe's length also affects movement; longer pipes experience greater expansion and contraction.

External forces can profoundly impact pipe movement. Soil expansion and ground movement, often caused by changes in moisture content or seismic activity, can shift buried pipes. In buildings, structural settling or vibrations from nearby construction can stress plumbing systems.

Water pressure fluctuations within the pipes can cause movement, especially in systems with frequent pressure changes. The pipe's installation method and support system also influence its ability to move. Rigid mounting can restrict natural expansion, leading to increased stress on joints and fittings.

Lastly, the pipe's age and condition affect its response to these factors. Older pipes may become brittle and less able to accommodate movement, increasing the risk of leaks or breaks.

Common Materials and Their Properties

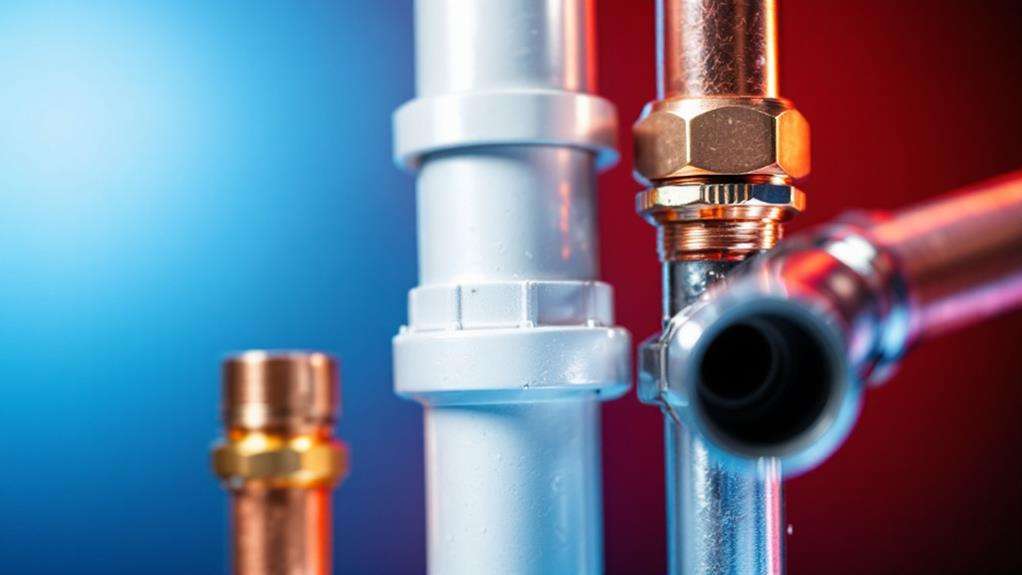

Plumbers encounter a variety of materials when working with pipes, each with unique properties that affect expansion and contraction. Understanding these materials' characteristics is essential for proper installation and maintenance.

Copper pipes are popular due to their durability and corrosion resistance. They have a relatively high coefficient of thermal expansion, meaning they're more prone to movement with temperature changes. PVC pipes, on the other hand, have a lower thermal conductivity and expand less than copper, making them suitable for both hot and cold water applications.

Steel pipes are known for their strength and heat resistance. They have a moderate coefficient of thermal expansion, falling between copper and PVC. When working with different materials, consider these factors:

- Thermal expansion rates

- Temperature range of the application

- Pipe diameter and length

Cast iron pipes have excellent thermal stability but are less common in modern plumbing due to their weight and installation challenges. CPVC pipes offer a balance between PVC and copper, with good thermal properties and chemical resistance. By understanding each material's unique properties, you'll be better equipped to handle expansion and contraction issues in your plumbing projects.

Risks of Unmanaged Pipe Expansion

Failure to address pipe expansion can lead to serious consequences in plumbing systems. When you neglect to manage thermal expansion, you're risking damage to your pipes, fittings, and connected appliances. Excessive stress can cause pipes to buckle, crack, or even burst, resulting in costly water damage and potential safety hazards.

Unmanaged expansion can also compromise the integrity of pipe joints, leading to leaks and reduced system efficiency. You might experience unusual noises, such as creaking or banging, as pipes struggle to accommodate temperature changes. In severe cases, this can result in complete system failure, requiring extensive repairs or replacement.

To mitigate these risks, it's imperative to implement proper thermal stress monitoring and pipe displacement monitoring techniques. These strategies help you identify potential issues before they escalate, allowing for timely interventions. By routinely assessing your plumbing system's performance and incorporating expansion joints or loops where necessary, you'll markedly reduce the likelihood of expansion-related problems. Remember, proactive management of pipe expansion not only protects your property but also guarantees the longevity and reliability of your plumbing system.

Expansion Joints and Loops

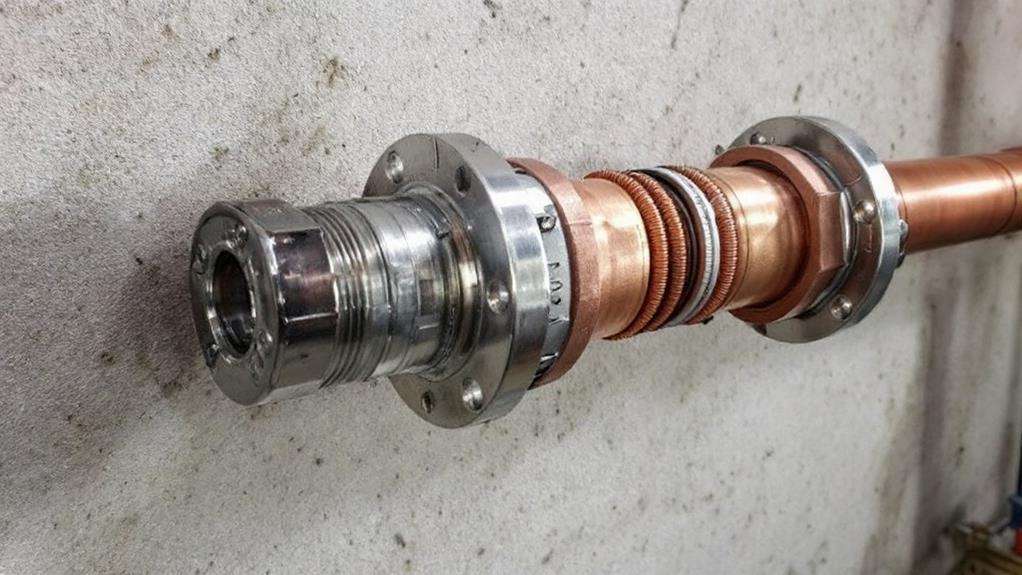

Expansion joints and loops are key solutions for managing pipe expansion in plumbing systems. They allow for controlled movement, preventing stress and damage to pipes and fittings. You'll find various types of expansion joints, including flexible couplings and expansion compensators, each designed to absorb thermal expansion and contraction.

When installing expansion joints, consider these important factors:

- Placement: Position joints at strategic points where movement is most likely to occur.

- Material compatibility: Guarantee the joint material is compatible with your piping system.

- Pressure rating: Select joints that can withstand your system's maximum operating pressure.

Expansion loops offer an alternative solution, using the pipe's inherent flexibility to accommodate movement. You can create loops by incorporating U-shaped bends or offsets in your piping layout. These loops absorb expansion and contraction, reducing stress on the system.

Pipe Supports and Anchors

Complementing expansion joints and loops, pipe supports and anchors play an essential role in managing thermal expansion and contraction. They're designed to secure pipes while allowing for controlled movement, preventing excessive stress on the plumbing system.

You'll find various types of pipe supports, including hangers, brackets, and pipe clamps. These components distribute the weight of the pipes evenly and maintain proper alignment. When selecting supports, consider the pipe material, size, and expected temperature fluctuations.

Anchors, on the other hand, are fixed points that limit pipe movement in specific directions. They're strategically placed to guide expansion and contraction along predetermined paths, reducing the risk of damage to joints and fittings.

Don't forget about vibration dampeners, which absorb mechanical vibrations and reduce noise transmission through the piping system. These can be particularly useful in areas with pumps or other equipment that generate vibrations.

When installing pipe supports and anchors, ensure they're spaced correctly and can accommodate the expected thermal movement. Pay attention to manufacturer guidelines and local building codes to guarantee effective performance and compliance. Regular inspections and maintenance of these components will help preserve the integrity of your plumbing system over time.

Insulation and Temperature Control

How can insulation and temperature control contribute to managing pipe expansion and contraction? By implementing proper insulation and temperature control measures, you'll not only mitigate the effects of thermal expansion but also improve energy efficiency and prevent condensation.

Insulation acts as a barrier, reducing heat transfer between pipes and their surroundings. This helps maintain consistent temperatures, minimizing expansion and contraction cycles. When selecting insulation, consider factors such as pipe material, ambient conditions, and temperature differentials.

Temperature control systems, such as thermostats and mixing valves, can regulate water temperature within pipes, further reducing expansion and contraction. These systems also contribute to energy efficiency by preventing unnecessary heating or cooling.

To effectively manage pipe expansion and contraction through insulation and temperature control:

- Choose appropriate insulation materials based on pipe type and environmental conditions

- Install insulation properly, ensuring complete coverage and proper thickness

- Implement temperature control devices to maintain consistent water temperatures

Designing for Thermal Stress

When it comes to designing for thermal stress, you'll need to account for the inevitable expansion and contraction of pipes. Start by evaluating the materials you're using and their coefficient of thermal expansion. Different materials react differently to temperature changes, so choose wisely based on your project's requirements.

Consider the layout of your plumbing system and identify areas where thermal stress is likely to occur. Install expansion joints or loops at strategic points to absorb movement and prevent damage. These devices allow pipes to flex without compromising their integrity.

Don't forget to factor in thermal conduction and heat transfer processes when designing your system. Proper insulation can help minimize temperature fluctuations and reduce stress on pipes. Use flexible connections between pipes and fixed points to accommodate movement.

Pay attention to support systems and anchoring methods. Allow for some flexibility in pipe hangers and supports to prevent restricting movement. When running pipes through walls or floors, leave enough clearance for expansion and contraction.

Maintenance and Inspection Practices

Regular maintenance and inspection are essential for preventing pipe expansion and contraction issues. By conducting regular inspections, you'll be able to identify problem areas before they become major concerns. Look for signs of stress, such as bowing pipes, loose fittings, or visible damage to insulation. Pay special attention to areas where pipes pass through walls or floors, as these are common spots for expansion-related problems.

To maintain your plumbing system effectively:

- Schedule routine inspections at least twice a year, focusing on both visible and concealed piping.

- Check expansion joints and flexible connectors for wear, ensuring they're functioning properly.

- Monitor temperature fluctuations in your building, as extreme changes can exacerbate expansion issues.

When identifying problem areas, use thermal imaging cameras to detect unusual temperature variations along pipe runs. This can help pinpoint potential weak spots where expansion and contraction are causing stress. Don't forget to inspect pipe supports and hangers, adjusting them as needed to accommodate movement. By staying proactive with your maintenance practices, you'll minimize the risk of pipe failure and extend the lifespan of your plumbing system.