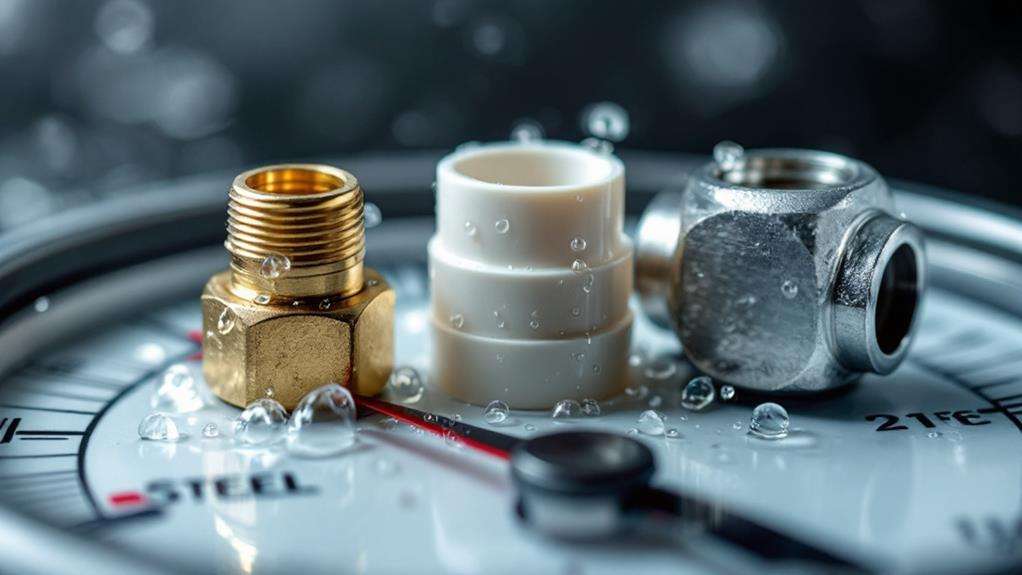

When to Use Brass, Plastic, or Steel Fittings in Plumbing

Choose brass fittings for hot water systems, high-pressure applications, and areas with corrosive water due to their durability and antimicrobial properties. Opt for plastic fittings in low to moderate pressure systems, cold water lines, and when cost-effectiveness is essential. They're also great for chemical resistance. Steel fittings excel in high-pressure industrial settings and can withstand extreme temperatures, but they're prone to corrosion. Always consider local building codes, water quality, and specific application requirements when selecting fittings. The right choice depends on factors like pressure, temperature, and chemical compatibility. Diving deeper into each material's strengths and weaknesses will help you make the best decision for your plumbing project.

Understanding Plumbing Fitting Materials

The humble pipe fitting, often overlooked, plays an essential role in any plumbing system. When choosing fittings, you'll encounter various materials, each with unique properties and applications. Understanding these materials is pivotal for creating a reliable and efficient plumbing network.

Brass fittings are known for their durability and corrosion resistance. They're ideal for hot water systems and areas with high mineral content. Plastic fittings, such as PVC and PEX, offer excellent moisture resistance and are lightweight, making them perfect for cold water lines and DIY projects. Steel fittings, including galvanized and stainless steel, provide strength and corrosion protection, making them suitable for outdoor applications and high-pressure systems.

Consider factors like water temperature, pressure, and local building codes when selecting fitting materials. Brass excels in hot water applications, while plastic is budget-friendly and easy to install. Steel offers superior strength but may be prone to rust if not properly treated. By understanding the strengths and weaknesses of each material, you'll be better equipped to make informed decisions for your plumbing projects, ensuring longevity and paramount performance of your system.

Brass Fittings: Pros and Cons

Workhorses of the plumbing world, brass fittings have long been favored for their durability and versatility. You'll find these fittings in various applications, from residential to industrial settings. Their corrosion resistance makes them ideal for both hot and cold water systems, giving you peace of mind with regards to longevity.

When considering brass fittings, you'll appreciate their strength and ability to withstand high pressures. They're also heat-resistant, making them suitable for steam applications. Another advantage is their antimicrobial properties, which can help reduce bacterial growth in your plumbing system.

However, brass fittings aren't without drawbacks. They're more expensive than plastic alternatives, which might impact your budget for larger projects. Lifespan considerations come into play as well; while brass fittings can last decades, they may eventually develop issues like dezincification in certain water conditions.

You should also be aware that some brass fittings contain lead, which can leach into your water supply. To address this concern, look for lead-free brass fittings that comply with current regulations. Despite these factors, brass fittings remain a popular choice for many plumbing applications due to their reliability and performance.

Plastic Fittings: Advantages and Disadvantages

Shifting gears from brass, let's examine plastic fittings in plumbing systems. Plastic fittings offer several advantages that make them a popular choice for many applications. You'll find them easy to install, thanks to their lightweight nature and simple connection methods. Their corrosion resistance is another significant benefit, ensuring longevity in various environments.

Plastic fittings are also cost-effective, often being cheaper than their metal counterparts. They're ideal for use with hot and cold water lines, as well as in drain and waste systems. You'll appreciate their flexibility, which can help absorb shock and reduce noise in your plumbing.

However, plastic fittings aren't without drawbacks. They're generally less durable than metal options and can degrade over time, especially when exposed to UV light or extreme temperatures. You'll need to be cautious during installation, as overtightening can cause cracks or leaks. Additionally, plastic fittings may not be suitable for high-pressure applications or in areas with strict fire codes. Consider your specific needs and local regulations when deciding if plastic fittings are the right choice for your plumbing project.

Steel Fittings: Strengths and Weaknesses

Steel powerhouses in the plumbing world, fittings made from this sturdy metal offer unparalleled strength and durability. You'll find that steel fittings can withstand high pressures and temperatures, making them ideal for industrial applications and large-scale plumbing systems. Their dependable nature guarantees they won't crack or break under stress, providing long-lasting reliability.

However, steel fittings aren't without their drawbacks. While some types offer decent corrosion resistance, they're generally more susceptible to rust than brass or plastic alternatives. This vulnerability can lead to potential leaks and contamination over time, especially in areas with high moisture or exposure to chemicals.

You'll also need to take into account thermal expansion when using steel fittings. As temperatures fluctuate, steel expands and contracts more than other materials, which can cause stress on connections and potentially lead to leaks. To address this issue, you may need to incorporate expansion joints or loops in your plumbing design.

Despite these challenges, steel fittings remain a top choice for many plumbing professionals due to their strength and reliability. When properly installed and maintained, they can provide excellent service in various applications, from residential to industrial settings.

Water Pressure Considerations

Understanding water pressure is essential when selecting plumbing fittings. You'll need to consider the maximum pressure your system will experience and choose fittings that can withstand it. Brass fittings are excellent for high-pressure applications, as they're strong and durable. They also offer good corrosion resistance, making them suitable for long-term use in various water conditions.

Plastic fittings, while less expensive, may not be appropriate for high-pressure systems. They're better suited for low to moderate pressure applications. However, they do offer excellent corrosion resistance and are lightweight, making installation easier.

Steel fittings can handle high pressures but may corrode over time, especially in areas with aggressive water. If you're using steel, consider galvanized or stainless options for better longevity.

Water flow rate is another pivotal factor. Brass and steel fittings generally allow for higher flow rates than plastic ones. If you need to maintain a specific flow rate, make sure your chosen fittings can accommodate it without restricting water movement.

Always check local building codes and manufacturer specifications when selecting fittings. They'll provide guidance on pressure ratings and appropriate uses for each material.

Temperature Impact on Fitting Choice

Temperature plays an essential role in selecting the right plumbing fittings. When considering temperature impact, you'll need to account for both the fluid temperature inside the pipes and the ambient temperature surrounding them. Brass fittings excel in high-temperature applications, making them ideal for hot water lines and steam systems. They're also resistant to corrosion, even in extreme temperatures. Plastic fittings, on the other hand, are better suited for cold water lines and moderate temperatures. They're lightweight and cost-effective but can degrade when exposed to high heat.

Steel fittings offer excellent durability and strength across a wide temperature range, but they're susceptible to rust and corrosion. When choosing fittings, consider:

- Thermal expansion rates of different materials

- Insulation requirements for various temperature ranges

- Potential for freeze-thaw cycles in your climate

Don't forget to factor in thermal expansion when designing your plumbing system. Different materials expand and contract at varying rates, which can lead to leaks or damage if not properly accounted for. Insulation requirements also play a pivotal role in maintaining consistent temperatures and preventing heat loss or gain. By carefully considering temperature impacts, you'll guarantee your plumbing system performs flawlessly and lasts longer.

Chemical Compatibility in Plumbing

Chemical compatibility is an essential factor when selecting plumbing fittings. You'll need to consider the types of substances that will flow through your pipes and how they might interact with different fitting materials. Brass fittings offer excellent corrosion resistance against many chemicals, making them suitable for various applications. However, they may not be ideal for water with high chlorine content or acidic solutions.

Plastic fittings, such as PVC or CPVC, are highly resistant to a wide range of chemicals, including acids, bases, and salts. They're often used in industrial settings where chemical exposure is a concern. However, some organic solvents can degrade certain plastics, so it's pivotal to check compatibility charts before installation.

Steel fittings, particularly stainless steel, provide outstanding resistance to many corrosive chemicals. They're often used in harsh environments or when dealing with aggressive substances. However, chlorides can cause pitting in some stainless steel grades, so you'll need to select the right alloy for your specific application.

When selecting fittings, always consult chemical resistance charts and think about the specific substances your plumbing system will encounter to guarantee long-term performance and safety.

Building Codes and Regulations

A maze of rules and standards governs the selection and installation of plumbing fittings in buildings. You'll need to traverse through local, state, and national regulations to guarantee your plumbing work is up to code. These rules are designed to protect public health, safety, and the environment.

Before starting any plumbing project, you must familiarize yourself with permit requirements and local code compliance. Most jurisdictions require permits for significant plumbing work, and you'll need to submit detailed plans for approval. Inspections are typically required at various stages of the project to verify compliance.

When choosing fittings, consider these code-related factors:

- Material restrictions for specific applications

- Pressure ratings for different pipe sizes

- Compatibility with potable water systems

Building codes often dictate the types of fittings allowed for certain uses. For example, some areas prohibit using plastic fittings in commercial buildings or high-rise structures. You'll also need to adhere to specific installation methods, such as proper support and spacing of pipes.

Cost Comparison of Fitting Materials

When you're planning a plumbing project, the cost of fittings can substantially impact your budget. It's crucial to consider the price points of different materials to guarantee cost effectiveness without compromising quality.

Plastic fittings, such as PVC and PEX, are generally the most affordable option. They're lightweight, easy to install, and resistant to corrosion. However, they may not be suitable for all applications, especially in high-temperature or high-pressure systems.

Brass fittings fall in the mid-range price category. They're durable, corrosion-resistant, and can handle higher temperatures and pressures than plastic. While more expensive than plastic, brass fittings often provide better long-term value due to their longevity.

Steel fittings, particularly stainless steel, are typically the most expensive option. They're extremely durable and can withstand harsh conditions, making them ideal for industrial applications. However, their high cost may not be justified for residential use unless specific circumstances require their superior strength and corrosion resistance.

When comparing costs, don't forget to factor in installation time and potential replacement expenses. Sometimes, a higher upfront cost can lead to savings in the long run through reduced maintenance and longer lifespan.

Application-Specific Fitting Recommendations

Choosing the right plumbing fittings for specific applications is essential for ensuring ideal performance and longevity of your plumbing system. When deciding between brass, plastic, or steel fittings, consider the specific requirements of your project.

For outdoor applications exposed to the elements, opt for brass fittings. They offer excellent corrosion resistance and can withstand harsh weather conditions. In hot water systems, brass is also a top choice due to its ability to handle high temperatures without degrading.

Plastic fittings are ideal for cold water supply lines and drain systems. They're lightweight, affordable, and resist chemical corrosion. However, they're not suitable for high-temperature applications.

Steel fittings excel in high-pressure systems and industrial settings. They offer superior strength and durability but may require additional corrosion protection in certain environments.

Consider these factors when selecting fittings:

- Water quality and chemical composition

- Temperature range of the system

- Pressure requirements

Remember to factor in lifespan expectations when choosing materials. Brass and steel fittings generally last longer than plastic, but proper installation and maintenance are pivotal for maximizing the longevity of any fitting type. Always consult local building codes and manufacturer recommendations to ensure compliance and peak performance.