Pipe Fittings for Beginners: Understanding Different Sizes and Types

Pipe fittings are vital components in plumbing and construction that connect pipes, change direction, or adapt sizes. You'll encounter various types, including elbows, couplings, reducers, and tees, each serving a specific purpose. Understanding pipe fitting sizes involves grasping nominal pipe size (NPS) and pipe schedule concepts. Materials range from metals like brass and copper to plastics like PVC. When choosing fittings, consider factors such as fluid type, pressure, and environmental conditions. Proper installation requires cleaning, applying sealant, and correct tightening. Regular maintenance guarantees longevity and prevents leaks. By becoming an expert in these basics, you'll be well-equipped to tackle your next plumbing project with confidence.

What Are Pipe Fittings?

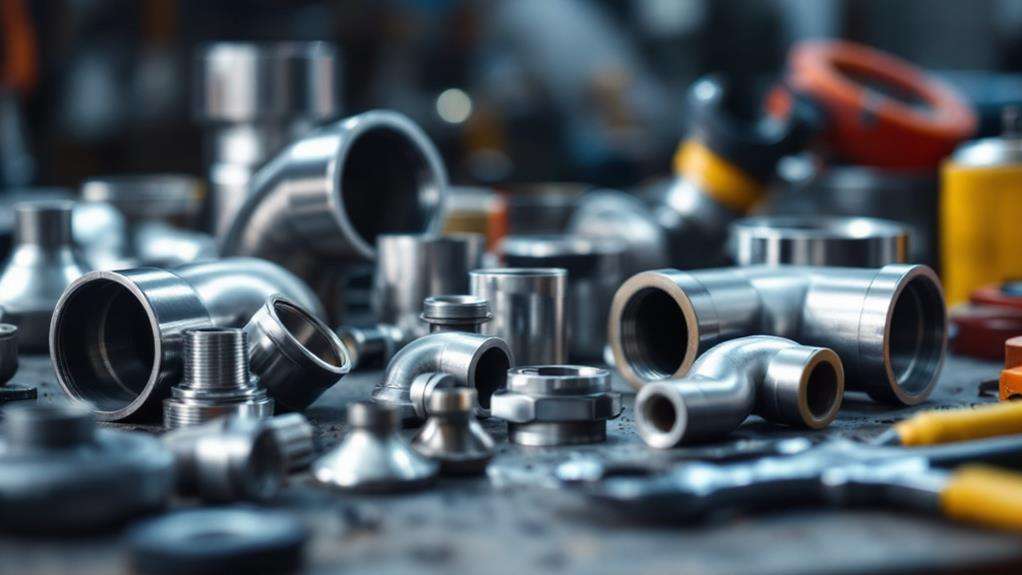

Plumbers and DIY enthusiasts alike rely on pipe fittings as essential components in any piping system. These indispensable connectors are designed to join pipes, change their direction, or adapt their size. Pipe fittings come in various shapes, sizes, and materials, each serving a specific purpose in your plumbing or construction project.

When you're working with pipes, you'll encounter fittings made from different materials such as PVC, copper, brass, or steel. The pipe composition you choose depends on factors like the intended use, pressure requirements, and environmental conditions. Fittings are engineered to match the pipe material they're connecting, ensuring a secure and leak-free joint.

The pipe function determines which type of fitting you'll need. For example, elbows are used to change a pipe's direction, while couplings join two pipes of the same diameter. Reducers allow you to connect pipes of different sizes, and tees create branch lines. Understanding these basic fitting types will help you manage your plumbing projects more effectively. As you become familiar with pipe fittings, you'll be better equipped to tackle various plumbing tasks and create efficient, reliable piping systems.

Common Types of Pipe Fittings

When it comes to pipe fittings, you'll encounter several common types that are vital for most plumbing projects. These fittings come in various pipe connection configurations and fitting joint types to suit different needs.

Elbows are one of the most frequently used fittings, allowing you to change the direction of pipes at different angles, typically 45 or 90 degrees. Couplings join two pipes of the same diameter, while reducers connect pipes of different sizes. Tees are T-shaped fittings that enable you to create branch lines off the main pipe.

Unions provide a convenient way to disconnect pipes without cutting them, making maintenance easier. Caps and plugs seal off pipe ends, while nipples are short pipe sections used to extend or connect fittings. Adapters allow you to join pipes with different thread types or sizes.

For larger systems, you might use flanges to connect pipes or attach them to equipment. Valves, though not strictly fittings, are indispensable components that control flow within your piping system. Understanding these common types of pipe fittings will help you choose the right ones for your specific plumbing needs.

Understanding Pipe Fitting Sizes

Now that you're familiar with common pipe fittings, it's indispensable to understand their sizes. Pipe dimensions are typically described using two measurements: nominal pipe size (NPS) and pipe schedule. The NPS refers to the approximate inner diameter of the pipe, while the schedule indicates the pipe's wall thickness.

When selecting pipe fittings, you'll need to match both the NPS and schedule to ensure a proper fit. It's pivotal to note that the actual pipe diameters may differ slightly from the nominal size. For example, a 1-inch NPS pipe has an actual outer diameter of 1.315 inches.

Pipe schedules range from 5 to 160, with higher numbers indicating thicker walls. The most common schedules are 40 and 80. As the schedule number increases, the inner diameter decreases while the outer diameter remains constant.

To accurately measure pipe size, use a caliper to determine the outer diameter. Then, consult a pipe size chart to find the corresponding NPS. Remember that different materials, such as PVC and steel, may have slight variations in their sizing standards.

Materials Used in Pipe Fittings

Along with size considerations, the materials used in pipe fittings play a crucial role in their performance and longevity. You'll encounter various materials, each with unique properties suited for different applications.

Metal fittings are common, with options like brass, copper, and stainless steel. Brass fittings offer excellent corrosion resistance and are often used in plumbing systems. Copper fittings are known for their durability and heat conductivity, making them ideal for both water and gas lines. Stainless steel fittings boast superior strength and corrosion resistance, perfect for harsh environments.

Plastic fittings, such as PVC and ABS, are lightweight and affordable alternatives. They're resistant to chemicals and corrosion, making them suitable for various applications. PVC is commonly used in drainage and irrigation systems, while ABS is often found in waste and vent pipes.

Cast iron fittings are durable and fire-resistant, making them popular in commercial and industrial settings. They're often used in soil and waste systems due to their sound-dampening properties.

When choosing pipe fittings, consider the metal composition and corrosion resistance requirements of your specific project. Each material has its strengths and weaknesses, so select the one that best suits your needs.

Choosing the Right Pipe Fitting

Armed with knowledge about materials, you're ready to tackle the task of selecting the right pipe fitting for your project. When choosing fittings, consider the type of fluid or gas you'll be transporting, the pressure requirements, and the environmental conditions. These factors will help you narrow down your options and guarantee compatibility with your system.

Start by determining the size and type of pipe you're working with. Measure the pipe's diameter and thread type to verify a proper fit. Next, identify the specific connection you need, such as an elbow, tee, or coupling. Consider the flow direction and any changes in pipe size or material when selecting appropriate connections.

Don't forget to account for expansion, contraction, and vibration in your system. You may need to incorporate flexible fittings or expansion joints to accommodate these factors. Additionally, think about future maintenance and accessibility when determining necessary components. Unions and flanges can make disassembly easier for repairs or replacements.

Installing Pipe Fittings Correctly

Proper installation is crucial for the longevity and effectiveness of your pipe system. When installing pipe fittings, you'll need to follow specific steps to guarantee a secure and leak-free connection. Start by cleaning the pipe ends and fittings thoroughly, removing any dirt, debris, or old sealant. Next, apply an appropriate pipe joint compound or thread tape to create a watertight seal.

For threaded fittings, wrap the male threads with thread tape in a clockwise direction, making sure to cover all threads evenly. When tightening the fitting, use the correct tools and avoid over-tightening, which can damage the threads or crack the fitting. For solvent-welded fittings, apply the proper solvent cement to both the pipe and fitting, then quickly insert the pipe into the fitting and hold it in place for the recommended time.

To avoid common installation mistakes, always double-check your measurements and ensure you're using the correct size and type of fitting for your application. Don't forget to allow for proper drying or curing time before pressurizing the system. By following these proper joint sealing techniques and best practices, you'll create a reliable and durable pipe system.

Maintaining Your Pipe Fittings

Regular maintenance of your pipe fittings is essential for guaranteeing the longevity and efficiency of your plumbing system. By routinely inspecting and caring for your fittings, you'll prevent costly repairs and extend their lifespan. Start by checking for leaks, which can often be detected by looking for water stains, dampness, or unusual odors. Don't forget to inspect for corrosion, especially in metal fittings, as this can lead to weakness and eventual failure.

To maintain your pipe fittings effectively, follow these key steps:

- Clean fittings regularly to remove buildup and debris

- Tighten loose connections to prevent leaks

- Apply pipe thread sealant when reassembling fittings

- Replace worn-out washers and gaskets promptly

- Keep an eye out for signs of wear, such as cracks or discoloration

When inspecting for corrosion, pay close attention to areas where different metals meet, as these are prone to galvanic corrosion. If you notice any signs of rust or deterioration, address the issue immediately to prevent further damage. By incorporating these maintenance practices into your routine, you'll guarantee your pipe fittings remain in top condition, providing reliable service for years to come.