Essential Guide to Choosing and Using Pressure Pumps

When choosing a pressure pump, consider your specific needs and the pump's capabilities. Match the flow rate and pressure to your system requirements, and evaluate fluid properties like viscosity and temperature. Select efficient pumps that can handle your application's demands while reducing operational costs. During installation, guarantee proper integration with your existing setup and implement necessary safety measures. Regular maintenance is indispensable for optimal performance—inspect critical components, analyze vibration patterns, and replace worn parts promptly. Always comply with safety regulations and manufacturer guidelines. By understanding these key aspects, you'll be well-equipped to make informed decisions about pressure pumps and maximize their effectiveness in your operations.

Types of Pressure Pumps

When selecting a pressure pump, you'll encounter several distinct types, each with its own strengths and applications. To choose the right pump for your needs, you'll need to ponder factors such as the fluid's viscosity, required pressure, and flow rate.

Reciprocating pumps, like piston and plunger designs, are your go-to choice for handling thick fluids and greases. They're sturdy and can generate high pressure, making them ideal for demanding applications. If you're dealing with viscous fluids and need effectiveness, rotary pumps such as gear, lobe, and screw pumps offer reliable performance.

For high-pressure output and high flow rates, centrifugal pumps are your best bet. These pumps, including multi-stage and axial-flow designs, excel in applications requiring significant fluid movement. If you need precise flow control for corrosive or viscous liquids, diaphragm pumps provide both high pressure and accuracy.

Lastly, if your application involves cleaning or cutting, consider high-pressure water jetting pumps. These specialized pumps deliver a powerful water-blasting effect, making them highly efficient for such tasks. By matching your specific needs to the right pump type, you'll achieve optimal performance and efficiency in your pressure pump system.

Key Selection Criteria

After you've identified the type of pressure pump you need, it's indispensable to ponder several key selection criteria to guarantee excellent performance and durability. Your pump selection should start with matching the flow rate to your system's requirements. This ensures optimal pump performance and prevents inefficiencies or potential failures.

Next, consider the pressure handling capabilities of the pump. It's pivotal to align these with your system's pressure needs to avoid performance issues or damage. Don't overlook fluid properties when making your choice. The pump must be compatible with the viscosity, temperature, and chemical composition of the fluid you're working with.

Four additional factors to keep in mind:

- Efficiency: Higher pump efficiency reduces operational costs and energy consumption

- Materials of construction: Choose materials that can withstand your specific fluid properties

- Pump size: Ensure it fits your space constraints and meets your flow rate needs

- Maintenance requirements: Consider long-term upkeep and availability of spare parts

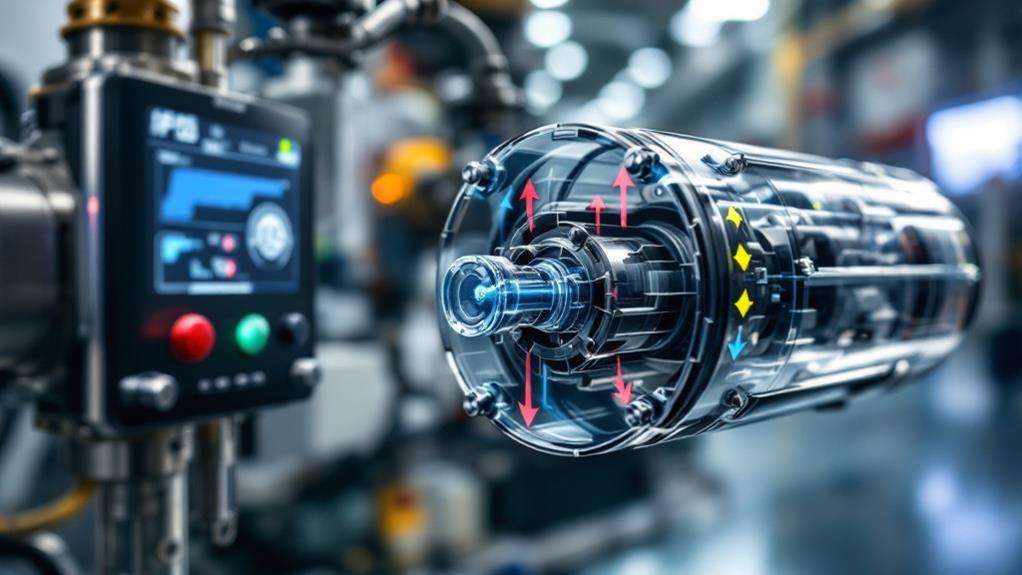

Pump Performance Optimization

Peak performance is the ultimate goal for any pressure pump system. To achieve paramount pump performance optimization, you'll need to focus on several key factors. First, consider efficiency to reduce energy consumption. This means choosing the right pump that meets your specific needs for high pressure and flow rates. Centrifugal pumps are often ideal for handling low-viscosity fluids, while positive displacement pumps work better with viscous liquids.

Monitor pressure and flow regularly to guarantee your pump operates within its designed parameters. If you notice any deviations, adjust the system accordingly. Recurring maintenance is indispensable for keeping your pump running smoothly. This includes cleaning, lubricating, and replacing worn parts as needed.

To further optimize performance, consider installing variable frequency drives to control pump speed and match output to demand. Proper pipe sizing and layout can also minimize friction losses and improve overall efficiency. Don't forget to check for leaks or blockages that could impair pump function. By implementing these strategies, you'll maximize your pump's performance, extend its lifespan, and reduce operating costs. Remember, a well-optimized pump system is key to achieving peak efficiency and reliability in your operations.

Installation and System Integration

The successful installation and system integration of pressure pumps are essential steps that can make or break your pump's performance. When you choose the best type of pump that meets your needs, you're only halfway there. Proper installation and system integration are indispensable for ensuring efficiency and reliability.

To maximize your pump's performance, consider these key factors:

- Accessibility: Install your pump in a location that's easy to maintain, with accessible parts for routine checks and repairs.

- Connections: Guarantee all piping and electrical connections are secure and properly sized.

- Environment: Consider temperature, humidity, and potential contaminants in the installation area.

- Safety: Implement necessary safety measures, including proper ventilation and emergency shut-off systems.

When integrating your pump into your existing system, pay attention to compatibility issues. You'll need a pump that is easy to incorporate with your current setup. This may involve adapting piping, adjusting pressure settings, or upgrading control systems. Remember, a well-integrated pump system will operate more productively and require less maintenance over time. By focusing on proper installation and system integration, you'll guarantee your pressure pump performs at the highest level and reliably for years to come.

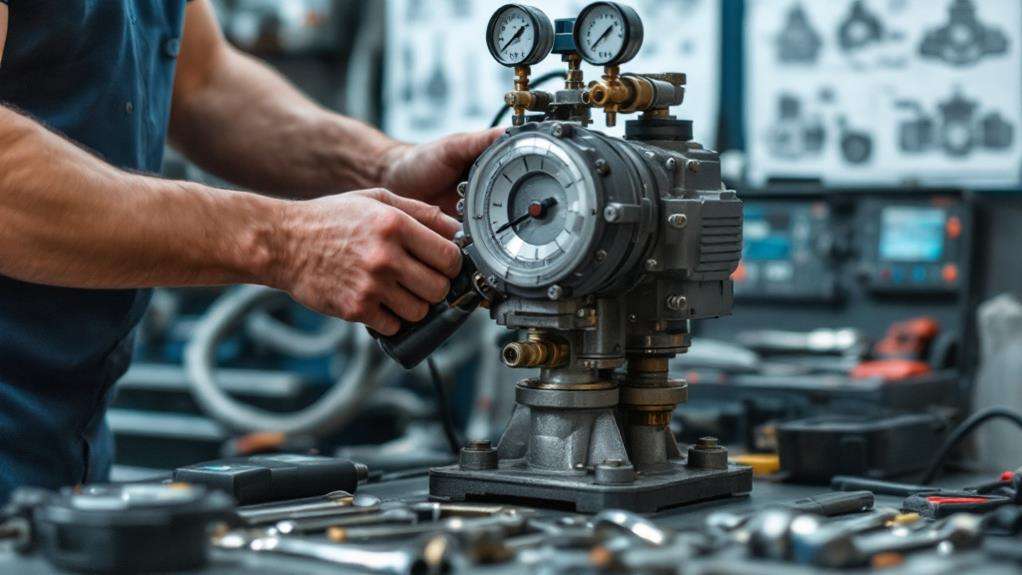

Maintenance and Troubleshooting

Regular maintenance and effective troubleshooting are essential for keeping your pressure pump running smoothly and efficiently. To ensure ideal performance and extend your pump's service life, you'll need to inspect critical components like seals, bearings, and impellers regularly. When issues arise, employ proper troubleshooting techniques, such as analyzing vibration patterns and measuring flow and pressure to identify the root cause of problems.

Maintaining a exhaustive maintenance log is vital. It'll help you track your pump's service history, identify recurring issues, and implement proactive maintenance strategies. Don't hesitate to replace worn or damaged parts promptly, following manufacturer recommendations to prevent further damage and improve overall reliability.

Pay close attention to start-up and shut-down procedures, as well as storage and handling guidelines. These practices will help preserve your pump's integrity and prevent premature failures. By following these maintenance and troubleshooting tips, you'll minimize unexpected downtime and costly repairs. Remember, a well-maintained pressure pump not only performs better but also saves you time and money in the long run.

Safety Considerations and Regulations

Safety should be your top priority when choosing and using pressure pumps. Compliance with safety standards and regulations, such as OSHA and ASME, is vital for protecting workers and preventing accidents. You'll need to guarantee your pressure pumps are equipped with mandatory safety features like pressure relief valves, which prevent equipment damage by releasing excess pressure.

For electric-powered pumps, proper grounding and electrical safety measures are essential to mitigate the risk of electric shocks or fires. Don't overlook the importance of extensive employee training on proper installation, operation, and maintenance procedures.

To maintain safe and reliable operation, you should:

- Conduct regular inspections for leaks and worn parts

- Check pressure readings frequently

- Perform routine maintenance as recommended by the manufacturer

- Keep detailed records of all safety checks and repairs