CPVC vs. PVC Pipes: What’s the Difference?

PVC and CPVC pipes are both popular plumbing materials, but they have key differences. CPVC can withstand higher temperatures (up to 200°F) compared to PVC (140°F), making it suitable for hot water applications. It's also more chemically resistant and durable. PVC is cheaper and more flexible, commonly used for residential plumbing and drainage. CPVC is preferred for industrial and commercial projects due to its superior properties. When choosing between the two, consider your project's temperature requirements, chemical exposure, and budget. While CPVC is more expensive, it may offer better long-term value in certain applications. Exploring these differences further will help you make the best choice for your plumbing needs.

Understanding PVC and CPVC

In the world of plumbing and piping, you'll often come across two popular materials: PVC and CPVC. Both are thermoplastic materials known for their strength, durability, and easy installation. PVC, or polyvinyl chloride, is widely used for its low cost and versatility in plumbing and drainage applications. It's typically white or dark gray and follows the Nominal Pipe Size standard.

CPVC, or chlorinated polyvinyl chloride, is a variation of PVC that undergoes a chlorination process, increasing its chlorine content. This modification allows CPVC to withstand higher temperatures up to 200°F, making it suitable for hot water applications and more demanding commercial and industrial uses. You'll recognize CPVC by its light yellowish or light gray color.

One key difference is that CPVC is available in both Nominal Pipe Size and Copper Tube Size standards, offering more flexibility in design and integration with existing systems. When it comes to joint connections, CPVC requires different primers and solvents compared to PVC. Understanding these distinctions will help you choose the right material for your specific plumbing needs, whether it's for unheated water systems or high-temperature fluid applications.

Temperature Resistance Comparison

One of the most significant differences between CPVC and PVC pipes lies in their temperature resistance. When you're considering which material to use for your piping needs, it's pivotal to understand these distinctions.

CPVC pipes can withstand temperatures up to 200°F, giving them a clear advantage over PVC pipes, which peak at 140°F. This higher temperature tolerance makes CPVC more suitable for applications involving hot water, steam, and high-temperature fluids. If you're working on industrial or commercial projects that require greater heat resistance, CPVC is likely the better choice.

PVC's limitations in temperature resistance make it less suitable for high-temperature applications. On the other hand, CPVC's superior thermal stability guarantees a longer lifespan and better performance in high-temperature environments. This makes CPVC particularly relevant in settings where consistent exposure to heat is expected.

When you're deciding between CPVC and PVC, consider the specific temperature requirements of your project. For standard plumbing needs, PVC may suffice. However, if you're dealing with hot water systems or industrial applications where heat tolerance is pivotal, CPVC's enhanced temperature resistance makes it the more dependable option.

Chemical Composition and Properties

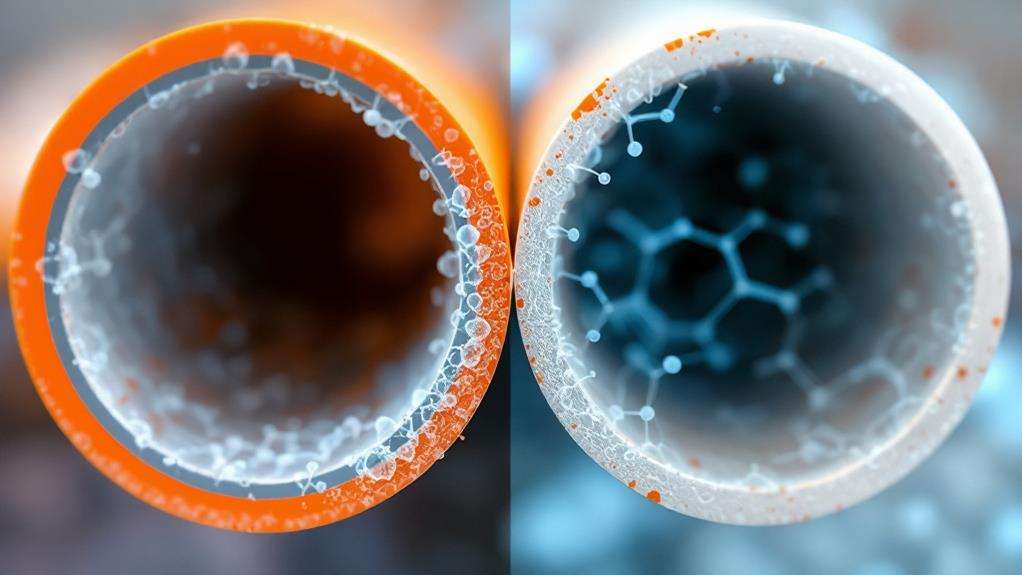

The molecular structure of CPVC and PVC pipes sets them apart in significant ways. Both are thermoplastics made of hydrogen, carbon, and chlorine, but CPVC has a higher chlorine content. This key difference in chemical composition gives CPVC enhanced properties that make it superior for certain plumbing applications.

The increased chlorine in CPVC results in a more rigid and durable pipe material. It can withstand temperatures up to 200°F, compared to PVC's 140°F limit. This makes CPVC a better choice for hot water lines where traditional copper pipes might have been used. Additionally, CPVC's chemical resistance is superior, allowing it to handle aggressive chemicals and corrosive substances that would degrade PVC.

You'll also find that CPVC has better insulating properties and is less likely to produce condensation on its surface. This can be beneficial in certain plumbing scenarios where temperature control is vital. However, it is essential to acknowledge that the different compositions of PVC and CPVC require specific primers and solvent cements for proper installation. You can't use the same joining materials interchangeably between these two pipe types.

Applications and Usage

When it comes to applications and usage, PVC and CPVC pipes each have their own strengths. PVC is commonly used for plumbing, venting, and drainage systems, making it a popular choice for residential and light commercial projects. However, if you're dealing with high-temperature fluids or need greater heat tolerance, CPVC is the way to go. It can withstand temperatures up to 200°F, compared to PVC's 140°F limit, making it ideal for industrial and commercial water applications.

CPVC is available in a wider range of options, including both nominal pipe sizes and copper tube sizes. This versatility allows for easier integration with existing piping systems and more flexibility in design. You'll find that CPVC Pipe is also more flexible and requires less stringent support, making it easier to install in complex layouts or tight spaces.

When it comes to PVC vs CPVC for chemical handling, CPVC takes the lead. Its superior chemical resistance makes it the preferred choice for industrial, chemical processing, and laboratory applications. If you're working with aggressive chemicals, CPVC's ability to withstand harsh substances gives it a clear advantage over PVC.

Cost and Installation Considerations

Choosing between PVC and CPVC pipes isn't just about performance; cost and installation factors play an essential role too. When it comes to material costs, PVC is considerably more budget-friendly, with Schedule 40 PVC costing about $0.40 per foot compared to $2.50 for CPVC. This nominal difference can add up quickly in larger applications.

Installation considerations also favor PVC. It's more flexible and requires less frequent support, needing brackets every four feet instead of CPVC's three-foot intervals. This can make PVC easier to work with, especially in drainage systems or other widely used applications. However, CPVC's flexibility can be advantageous in complex piping layouts, potentially reducing the need for additional fittings.

The joining process for these polyvinyl pipes differs as well. PVC uses a simpler solvent welding method, while CPVC requires specialized primers and solvents, which can increase installation costs. Despite the higher upfront expense, CPVC's superior temperature and chemical resistance may make it a better long-term investment for certain uses. When deciding between the two, consider both immediate costs and long-term benefits to determine which material best suits your specific application.